Wilkie Offshore uses new tech for innovative textiles

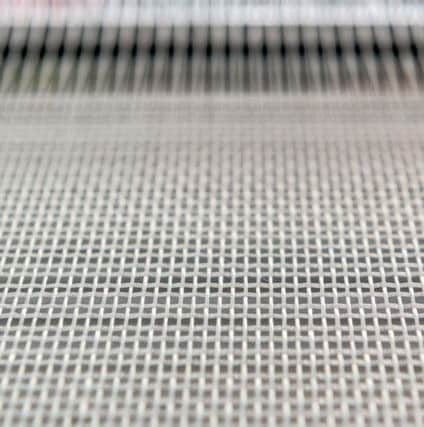

Wilkie Offshore was founded as jute weavers J&D Wilkie 148 years ago and has adapted over time to create a £20 million turnover business.

The company creates new advanced textile technology applications daily to support a wide range of customers.

Advertisement

Hide AdAdvertisement

Hide Ad“We create around 10 or 15 new textile technologies every week,” explains Jean-Christophe Granier, joint managing director of Wilkie Offshore.

“Our group business J&D Wilkie has an archive of over 20,000 different textiles and products. This wealth of technology is only possible because we have a proud history of adjusting to new markets. We continually strive to make our customers’ businesses even safer, even better.”

Wilkie Offshore processes and manufactures raw material fibres into textiles that perform in the oil and gas industry. The business has just opened a new factory in China and has ambitions to expand in the US.

Two years ago, the company realised others were supplying the oil and gas market on their doorstep and that there was a demand for their expertise.

“There is a huge amount of textile technology used offshore, but not always to best advantage,” explains Mr Granier.

“A textile specialist has the expertise to make offshore businesses safer, more efficient and more productive. We are the only ones in the market with this breadth of experience and the vision to apply our textile tech inventions to offshore production”

Wilkie Offshore’s contribution to a joint research and development product resulted in a revolutionary yarn which was woven into a new fibre called Wilkieflon™.

It is a key component used to develop unique and technically advanced composite technology. It is stronger, more durable and has better friction management than the current market leading brand. It can be an integral component in any offshore product where bearings must run dry, including rudders, turbines or centrifuges.

Advertisement

Hide AdAdvertisement

Hide AdWilkie Offshore’s invention, the WilkieBand, replaced an already established, proven technology. “Our customer tried something new and it paid off,” says Mr Granier, who sees this experimentation as evidence of a wider trend. “The downturn has sparked a genuine desire to consider new technology and a willingness to try new ways of doing things.”

Another strategic partnership means that Wilkie Offshore offers endless round slings, made out of Ultra High Molecular Weight Polyethylene (UHMWPE). These slings are eight times lighter than steel counterparts, but are 15 times stronger than steel on a weight-for-weight basis, all while retaining an industry-recognised safety factor of 7:1.

“We make our customers’ businesses safer. If you pick up a 60 tonne steel wire rope sling – that job requires three men. But you can pick up our sling safely with one man. It is soft so you can’t cut yourself on it like those made of steel wire. It is also eight times lighter than steel so the actual lift itself is less dangerous,” Mr Granier said.

“People find it difficult to fathom how many textiles are around you. A total of 75 per cent of a plane is textile. Everywhere I look I see textile.

“At the core of every invention, every product, in every sector and market, is our client’s challenge to operate in a different way. Each day we move our client’s challenge from back-of-an-envelope brainstorming, through the rigors of our DNV ISO 9001:2008 management system, to offshore application. This is the heart of great engineering: the satisfaction of genuinely improving our customers’ businesses.”

The best engineering is born of collaboration. “Wilkie Offshore acts like a collective: we engage partners and we’re frank with our customers about costs,” asserts Mr Granier. “We understand that all those who sit around the same table need to make a profit. We have always approached business this way.”

The Group has just invested in a new 180,000 square ft. factory in Jiaxing, Shanghai and plans expanding its Scottish fabrication and machining facility to accommodate the growing volume of orders.

Mr Granier is eager to find new challenges at Offshore Europe. “Set us your ultimate engineering challenge and we will show you that advanced textile technologies probably have more than one answer.”