Ferries Scotland: Inside Glen Sannox as hugely-delayed CalMac ferry nears completion at Ferguson Marine

It has smoke coming from its funnels, glass in its windows and electronic navigation screens operating on its bridge.

Our exclusive first pictures from on board the hugely-delayed ferry Glen Sannox show work entering its final phases as the troubled CalMac vessel nears completion at the Ferguson Marine shipyard in Port Glasgow, five years late.

Advertisement

Hide AdAdvertisement

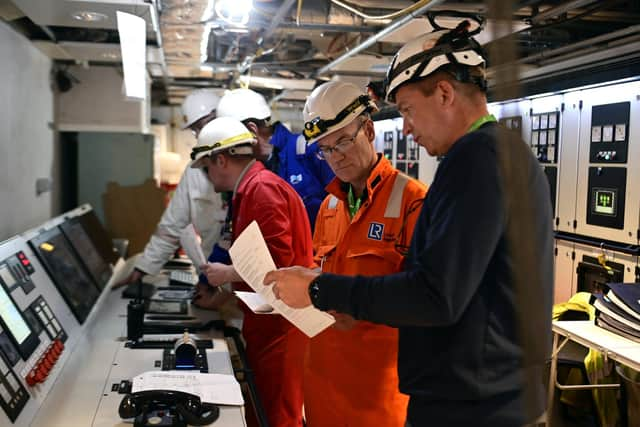

Hide AdFar from the largely-empty hull launched prematurely onto the Clyde with painted-on windows six years ago, the ship is now coming alive, its engines running, interiors being fitted out and systems checked over by certification firm Lloyd's.

"We're in really good shape,” said yard chief executive David Tydeman, sufficiently pleased with progress to invite The Scotsman to tour the vessel – and that he would hit the latest completion date this autumn after it was repeatedly put back.

He said: "I've been put on the spot before and I said I was confident previously, but this time I really do feel we're on track. We've made great progress over the last six months with getting the major systems, and ironing out the surprises we have continued to find over the last couple of years."

The ferry is scheduled to undergo sea trials from August to October then handed over to CalMac, which is due to conduct its own trials for two months before deploying the vessel on the main Arran route between Ardrossan and Brodick.

Mr Tydeman said the ship was more than 80 per cent complete, with only "minor" surprises still being found, adding: "The opportunity for major surprises is reducing all the time.”

He’s referring to the consequences of actions by former owner Jim McColl, which significantly increased the cost and length of the project prior to the yard going into administration and being nationalised by the Scottish Government in 2019.

Mr Tydeman said: "It's like they laid the carpet before they put the concrete screed down, or they put the kitchen cupboards on the wall before they plastered the wall. There were lots of things done out of sequence like that that we've had to do twice or three times."

However, he is keen to change the narrative from the prolonged focus on delays and cost overruns to Glen Sannox, or hull 801, and its sister vessel, the still unnamed hull 802, which will be the second biggest ships in the CalMac fleet after Loch Seaforth on its Ullapool-Stornoway route.

Advertisement

Hide AdAdvertisement

Hide AdMr Tydeman said: "These are going to be great ships. There has been so much negative press over the years, but we've rather lost sight of what a wonderful specification they have – 1,000 passengers, major car decks, catering, luxurious lounges for passengers, reclining seats in the observation lounge. It's going to be a great experience."

The fit-out is starting to make Glen Sannox’s interior recognisable as a ferry, although flooring and other features remain hidden behind protective panels.

The ceilings are still a mass of cabling, but Mr Tydeman said the lighting is fitted and working. He said 99 per cent of the ship’s 180 miles of cabling had been installed and half of it is connected.

Computer consoles on both the bridge and in the control room beside the engine room are operating, although the equipment has been there so long its software has had to be upgraded.

Mr Tydeman said work was continuing on remaining tasks downwards from the top deck, where some 30 crew cabins are among the most complete areas. Work is also moving up from the engine room, with the car deck the last section to be finished.

He said: "We have got all the final finishings of ceilings and walls to go up, but that’s the cosmetic stuff. There’s a few systems still to commission and a lot of testing to do, as well as fitting the furniture. The servery area and galley are equipped and the fridges and cookers in place.”

But it’s been a long time coming – the ferries have been under construction for eight years compared to the scheduled three years.

Mr Tydeman, who joined the yard last year, said the labour involved would have been “very significantly” reduced if sections [or modules] of the ship had been fitted out before being installed in the vessel, rather than that work being completed on board.

Advertisement

Hide AdAdvertisement

Hide AdHe said “a lot of the problems were because of decisions made a long time ago to build an empty ship”, which “embedded a lot of the issues that we’ve spent years solving”. He added: "They put the welding and construction together that just didn’t think about the conventional shipbuilding processes.”

That led to Glen Sannox weighing 2,200 tonnes when it was launched, while 802 will be nearly one third heavier at about 3,000 tonnes when it is goes down the slipway – and be finally named – which is planned for the end of November. Mr Tydeman said: “That gives you an idea of how much more we’re planning to put inside before launch”.

He said 802 would be “structurally complete” by early summer and is due to be finished in late summer of next year. The two ships are expected to cost three times their original £97m contract.

Mr Tydeman said the previous owners had started work on the vessels – the largest and most complex the yard has ever built – in 2015, a year after it went into administration for the first time. with just 70 workers remaining. He said: “That’s not a daft decision provided you take time to plan it – and they didn’t. It’s as simple as that.”

But he said winning a contract to build part of the Royal Navy’s type 26 frigates for BAE Systems was “really important” both for the reputation of the yard and staff morale, “knowing there is something else after 802 – we need to see there’s light in the tunnel for a future”.

Comments

Want to join the conversation? Please or to comment on this article.