Airbus partners with hi-tech Strathclyde hub to propel Scottish space sector

In a further boost for Scotland’s burgeoning space sector, the University of Strathclyde’s Advanced Forming Research Centre (AFRC) will work with Airbus Defence and Space (Airbus DS) to create innovative space propellant tanks.

The two-year collaboration, funded by the European Space Agency, hopes to facilitate the return of fuel tank manufacturing to the UK and take advantage of export opportunities in the global satellite market. Formerly produced in the UK, Airbus DS currently purchases its fuel tanks from Germany or the US.

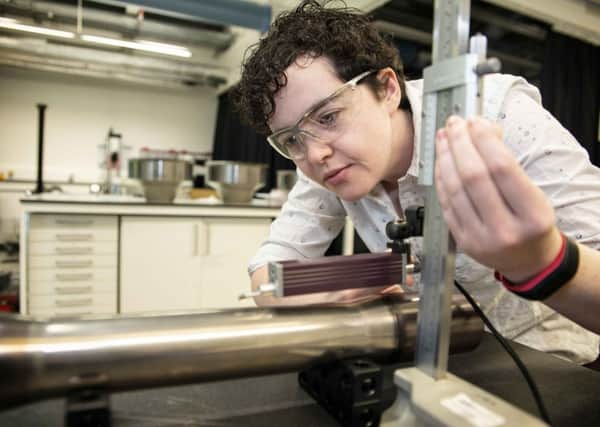

Inchinnan-based AFRC, a £60 million facility established in 2009, will use its forming and forging expertise to advise Airbus DS on advanced manufacturing methods for the tanks. These include creating more efficient and economical designs and “substantially reducing” machining time and waste of expensive metals, such as titanium.

The AFRC and Airbus DS will also collaborate with welding research organisation TWI to decide the chosen method for producing the tanks.

Jill Miscandlon, heading up the project at the AFRC, said: “Airbus DS will merge their own research experience with our study and decide on the chosen technique to take forward. This could be metal forming, superplastic forming or additive manufacturing processes.

“Key to the project is making components in a shorter lead-time and wasting less expensive material, which is essential with titanium alloys costing up to $60 [£50] per kilo, depending on alloy type and manufacturing route.

“We are also focused on sharing the project outputs with the wider supply chain here in the UK.”

Renato Bellarosa, head of tank products and research and technology manager at Airbus DS, added: “We still have independent supply chain processes in the UK, but we need to integrate them to make the tanks. This programme with the AFRC fits into a general roadmap that aims to develop this capability [in the UK].

“There is also export potential in the successful completion of this programme. We have customers overseas who are big players in satellite manufacture whom we believe would be interested in this new manufacturing approach.”

AFRC executive chairman Keith Ridgway said the project “highlights the benefits of aligning advanced manufacturing research with the UK’s growing space industry”.

Earlier this year the AFRC announced a tie-up with US industry heavyweight Spirit AeroSystems, which employs about 1,000 people at its Prestwick facility, to address key challenges facing the UK’s aircraft development industry.