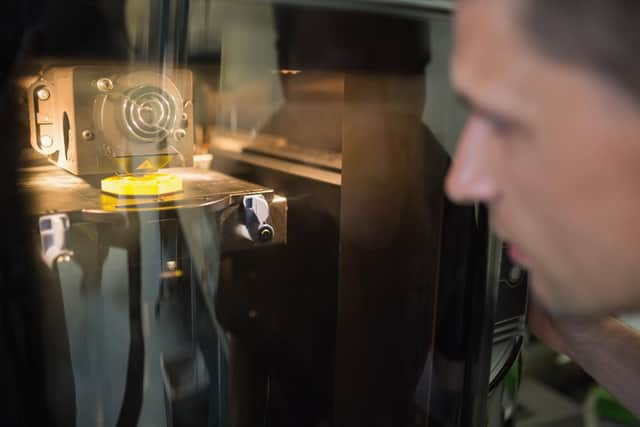

Scots SMEs gain £1m boost via project led by National Manufacturing Institute Scotland to capitalise on industrial 3D printing

A £1 million project has encouraged more than 100 small to medium sized enterprises (SMEs) across Scotland’s manufacturing industry to explore the potential of pioneering industrial 3D printing techniques expected to be able to add value, create greener products, and open up new commercial opportunities.

Those behind the three-year Additive Manufacturing Business and Technology Support (AM-Bats) initiative say it has helped small businesses across various sectors to learn more about how to design and adopt new processes, with the end goal of developing more sustainable products and entering new markets.

Advertisement

Hide AdAdvertisement

Hide AdThe programme was delivered by National Manufacturing Institute Scotland (NMIS) – operated by the University of Strathclyde and part of the High Value Manufacturing Catapult – and was funded through the Scottish Government’s Advancing Manufacturing Challenge Fund via the European Regional Development Fund.

A total of 36 projects have taken place, from renewable energy and electric vehicles to food and drink, sports, oil and gas, and medicine, and NMIS said many participating businesses have since created new products or changed existing ones to include 3D printed elements, while several have now adopted AM “due to the many benefits offered such as reduced development times, increased sustainability, design optimisation, faster time to market, and ability to utilise digital inventories”.

Among them, Confidence Plus received support from NMIS to develop a new product designed to support people using ileostomy bags, with several prototypes created for the new glider device made from recycled materials now being trialled.

Anne Inch, founder and managing director at the East Kilbride-based medical equipment manufacturer, said: “Working with NMIS on our medical device will enable us to access new markets, and could see the creation of new job opportunities in the healthcare manufacturing industry. The device aims to make a big difference to the lives of users of ileostomy bags, and we were grateful for the team’s support in exploring this new innovative technology.”

Additionally, Glaswegian eco-fashion brand Rocio, a Scottish Edge winner whose signature handbags are individually sculpted from sustainable wood, saw work on a new 3D-printed design that was showcased at Paris Fashion Week. Hamish Menzies, creative director at the firm, said: “For us, exploring the use of a 3D-printed prototype is more cost, time, and material-efficient in the long term. Through using this technology, we are one step closer to improving our endeavours to be even more sustainable, whilst unlocking and embracing the future capabilities of our industry.”

Another business, FluidMS that creates devices for 24/7 health exposure monitoring in manufacturing facilities, saw product assembly times reduced to ten minutes from 60 by taking part in the project, for example, while Stonehaven-based Whittaker Engineering saw lead times shortened from several months to nine days for its components used in the oil and gas sector.

Dickon Walker, polymer AM theme lead at NMIS, which is housed in a distinctive heather-coloured building at the heart of the Advanced Manufacturing Innovation District Scotland in Renfrewshire, said additive manufacturing has many advantages, but it can be “quite a daunting challenge” for SMEs in particular knowing how to get started. He added: “We’re pleased to see the impact now translating to new product development and the introduction of new production processes, all taking place here in Scotland.”

Comments

Want to join the conversation? Please or to comment on this article.