How wave energy is helping to boost traditional Scottish manufacturing

The Catapult Offshore Renewable Energy, ‘Tidal Stream Wave Energy Cost Reduction and Industrial Benefit' report published in 2018 calculated that wave energy would have a net cumulative benefit to the UK by 2040 of £4 billion.

Tim Hurst, managing director of Wave Energy Scotland (WES) says: “The study showed that of the £4bn that will be added to the UK economy, £1.5bn will stay in the domestic market, and £3.5bn will be the value of exports. There is a massive potential for exports because the global market for wave energy is so huge.”

WES runs the world's largest wave energy development initiative through five programmes: Power Take-off; Novel Wave Energy Converter; Structural Materials; Control Systems and Quick Connection Systems.

WES funding

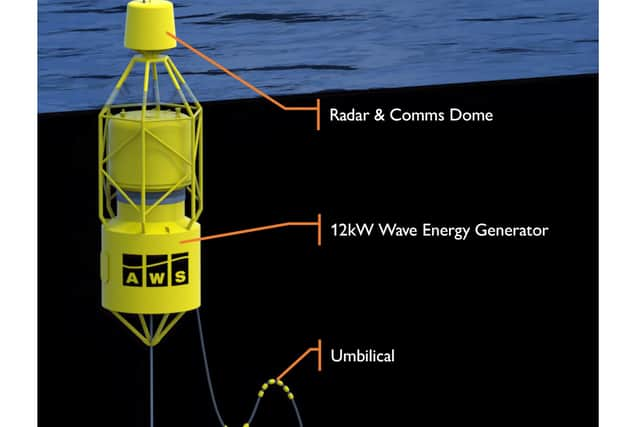

As part of the Novel Wave Energy Converter programme, two Scottish firms, Edinburgh-based Mocean Energy and AWS Ocean Energy from Inverness, received £7.7 million from WES to develop their technologies. The funding does not just benefit the lead companies, but also the wide range of contractors they work with to develop their devices in Scotland's fabrication yards.

In February, marine services company Malin Renewables was appointed by AWS to build its half-scale 'Archimedes Waveswing' device. Under the contract, worth £1m, the Waveswing is being fabricated and assembled at Malin's Westway Park site in Renfrew.

Ben Sharples, director of Malin Newbuild, says: “The wave energy industry is on an exciting journey, working to develop reliable, cost effective power generation devices. To actualise this ambition, and turn innovative ideas into practice, the wider skills of the maritime industry are required, with many specialists who have cut their teeth in oil and gas, shipbuilding or defence, bringing added value.”

He says the potential for the Malin Group, and the whole sector, is considerable. “As devices prove themselves at scale, there will then be a requirement to manufacture full size devices, in sufficient quantities to contribute to grid power production,” he explains. “As an organisation we have not only recently increased our manufacturing capacity through the establishment of three new business units, Malin Marine Services, Malin Newbuild and Malin Marine Equipment – but are also driving to realise our exciting vision of a marine technology hub on the banks of the Clyde.”

The Scottish Marine Technology Park (SMTP), being developed on brownfield land in Old Kilpatrick, will have production capacity to fulfil future demand, and a solid supplier infrastructure and central position, next to the Clyde, to enable deployment at sea.

Innovation fuelling growth

Sharples hopes that as projects, such as one with AWS, are successfully completed, more organisations will adopt such innovative technology and the volume of companies working in the sector will grow.

AJS Productions, a steel fabricator founded by director Raymond Imrie in Cowdenbeath in Fife six years ago to service the renewables sector, has been building a prototype, half-scale wave energy converter for Mocean that will soon be ready for testing in the water. He describes renewables, specifically wave and tidal energy, as the “bread and butter” of his business.

AJS has been involved in the Mocean project from the start, working closely with all the partners involved, including design engineers, Blackfish Engineering Design. Imrie describes this close and effective working relationship with others in the supply chain as one of AJS's “biggest assets”.

He is positive about the outlook for wave energy in Scotland, but says a challenge will be to meet demands to keep costs down. “Wave and tidal projects are getting funding, but they have to keep to that budget. We're always looking for savings for our clients, and we've been involved with so many devices we know where costs can be cut.”

He would like wave and tidal companies to continue to award contracts in Scotland rather than follow the path of the wind power sector which has taken business abroad. “It's not fair on the local economy to see big renewables projects going overseas,” he says.

Another business benefiting from renewables is Rybay Corrosion Services in Brechin, launched in 2016. It has been involved in a range of wave and tidal projects, including Mocean's energy converter.

David Jamieson, Rybay managing director, points to the positive impact WES and the range of wave energy projects is having. “Due to the funding available and the fact everyone wants to try and find the next big thing, there are lots of companies getting involved, investing money and trying to identify the most cost effective solutions to delivering as much green power as possible,” he explains.

In four years the contribution of renewables to Rybay's business has gone from about 10 per cent to 25 per cent.

While WES's Hurst is also optimistic about the future, he identifies the main challenge that needs to be addressed as the lack of a support mechanism to bring down the cost of wave energy in the way that has happened with wind power.