Harris tweed enjoys '˜strong year' despite Brexit upheaval

The industry produced 1.5 million metres of the cloth this year, down from 1.6m in 2015, but a substantial improvement on 2009 when output was 455,000m.

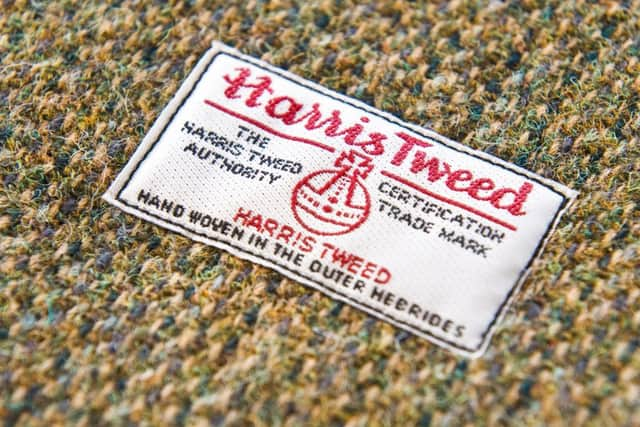

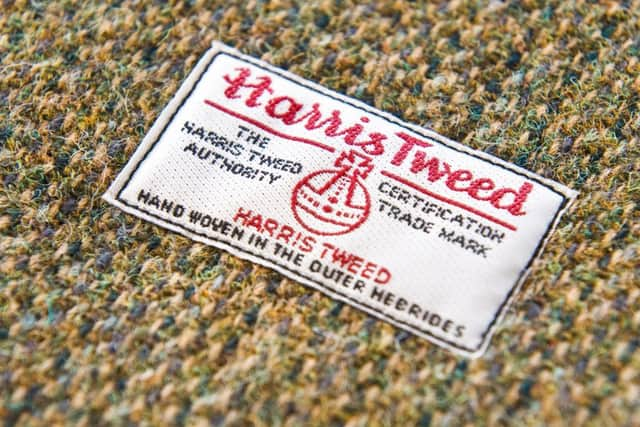

By law, Harris tweed can only be made from yarn that has been dyed and spun from pure virgin wool in the Outer Hebrides.

Advertisement

Hide AdAdvertisement

Hide AdThe Harris Tweed Authority, which released the figures, told The Scotsman 2016 “had been another very successful year for the industry”, which provides work for 300 people on the islands.

“In a small island economy that is no mean feat and something we should all be very proud of,” said Lorna Macaulay, chief executive of the authority.

“After five years of sustained year-on-year growth, we have witnessed a slight slowing downturn in certain markets and growth in others.

“Interiors and soft furnishing continues to be a strong segment of the market and the UK market likewise has held up very well.

“There is no doubt that there is some uncertainty in export markets in relation to the political climate. In an export driven business such as ours, it is vital that this uncertainty is minimised by Government.”

Around 70-80 per cent of Harris tweed is exported each year.

“All exporters in the UK are facing uncertainty but we’ve enjoyed a very strong 2016,” said Margaret Ann Macleod, brand development director at Harris Tweed Hebrides, one of three mills operating on the islands.

“January is when we see the bulk of our orders starting to arrive from our export customers. We’ve been busy sampling and developing relationships ahead of that and they’ve been going very well.

Advertisement

Hide AdAdvertisement

Hide Ad“The political uncertainty is concerning, but we are a UK-based company and all of our raw materials are bought here - we only buy Scottish wool. From that perspective we’re not too exposed to currency fluctuations right now.”

Macleod said the business had attracted “a lot of new customers” in 2016.

“Japan and other export markets have been strong for us,” she added. “The UK itself has been excellent, particularly for the interiors side of our business which we hope will continue to grow in 2017.

“Sustaining that business is what we’re focusing on. The industry has mushroomed in recent years. If we can continue our output at current levels in 2017 that will put us in an excellent position.”

Though the spinning process involved in the cloth’s production takes place at the three mills, the weaving must be done at the home of the weaver - using looms powered by nothing more than human effort.

The Harris Tweed Hebridies mill at Shawbost, on the west coast of the Isle of Lewis, employs more than 80 people.

Its reopening in 2007 was viewed as a significant step in securing a sustainable future for the industry, which had viewed as being on the verge of collapse.

But five years of growth have breathed a new optimism into the world of Harris tweed.

Advertisement

Hide AdAdvertisement

Hide Ad“We’re currently undertaking a £2m expansion programme for manufacturing facilities,” said Macleod. “We’re not the biggest private employer in the Outer Hebridies, but we’re not far off. Collectively, the industry certainly is after fish farming and processing.

“Harris Tweed remains enormously important to the economy of Lewis and Harris.”