Edinburgh-based Gravitricity lands deal with infrastructure major paving way to build hundreds of hydrogen stores across UK

The firm has signed a memorandum of understanding with infrastructure major VSL Systems UK – part of French giant Bouygues Construction group – to complete the design of purpose-built underground lined rock shafts that it says could be rolled out nationwide, and with plans to build a scale demonstrator in the next 24 months ahead of commercial roll-out.

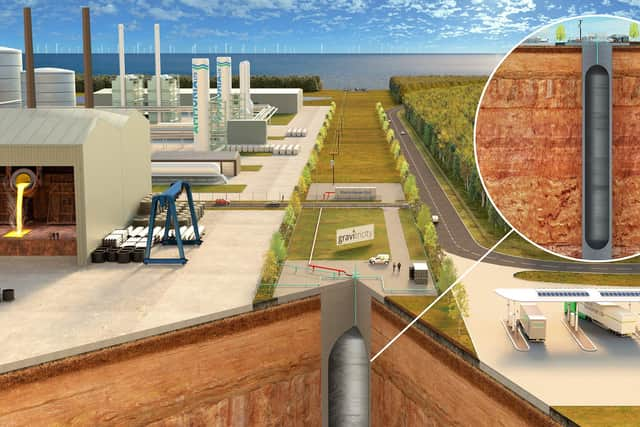

Gravitricity, which is developing relevant systems in the UK and mainland Europe, believes its technology known as FlexiStore is a “goldilocks” solution to the future challenge of green hydrogen storage – offering a system that is larger and more secure than above-ground hydrogen storage, and more flexible than subterranean salt caverns, the two most commonly-proposed alternatives.

Advertisement

Hide AdAdvertisement

Hide AdEach rock shaft would be six metres in diameter, 365m deep, and lined with steel, with a single store expected to hold up to 100 tonnes of green hydrogen – enough to refuel more than 1000 HGVs, or to power 500 buses for a week. Additionally, Gravitricity believes a single FlexiStore could store the green hydrogen generated by a 460-megawatt offshore wind farm and could be emptied and refilled daily.

The firm calculates that construction of just 1,000 such facilities would meet a quarter of the UK Government’s predicted 2050 hydrogen storage needs. It also says they can be built wherever required and are not dependent on specific geological locations (a drawback of salt caverns). This means single or multiple FlexiStores can be built close to renewable-powered green hydrogen production facilities where they can fuel hydrogen-powered industrial hubs and commercial hydrogen filling stations, added the Edinburgh-based business.

It is now seeking funds along with VSL to build its first scale demonstrator project in the UK, and has identified various potential sites. Once complete, Gravitricity then plans the roll-out of hundreds of purpose-built green hydrogen FlexiStores nationwide. The company added that it is in advanced discussions with Cumbrian steel specialist Bendalls Engineering to make the linings for the rock shafts.

Vital

Gravitricity MD Charlie Blair said: “Green hydrogen will be a vital fuel of the future in industrial applications and in heavy transport, where electrification is just not feasible, or where industrial grey hydrogen is already used. Purpose-built lined rock shafts will be the safest and most affordable way to store large volumes of hydrogen near to where it will be required. We believe we have a ‘Goldilocks’ solution which can be delivered safely and affordably to meet the growing hydrogen economy’s needs.”

Peter Hughes, MD of VSL UK – described as a specialist contractor for the construction, preservation and repair of major engineered structures and infrastructure – cheered the project, deeming it “fully aligned with the VSL vision to focus our engineering capabilities and solutions on the global transition to a low-carbon future”.

Gravitricity also said it recently completed a £300,000 feasibility study that it said showed that it is technically and commercially feasible to store large amounts of compressed hydrogen in an underground lined rock shaft. The business in November said it had secured six-figure funding to demonstrate its offering in India.

Comments

Want to join the conversation? Please or to comment on this article.